Ho:YAG laser at 2097 nm pumped by a narrow linewidth tunable 1.91 μm laser

Juntao Tian, Lili Zhao, Zhiyong Li, Jintian Bian, Qing Ye, Hai Wang & Rongqing Tan

Scientific Reports volume 13, Article number: 999 (2023) Cite this article

Abstract

This study presents a high efficiency Ho:YAG laser based on a narrow linewidth tunable 1.91 μm laser. A tunable Tm:YLF laser is the pump source and the wavelength continuous tunability ranges from 1906.04 to 1908.83 nm, corresponding to a linewidth of less than 0.41 nm. The tunable Tm:YLF laser is achieved by changing the operating temperature of the VBG. The output power of the Ho:YAG laser is between 21.04 and 23.53 W and the slope efficiency is between 64.08 and 68.26% at the pump power of 39.8 W. The output power and slope efficiency corresponding to the pump wavelength of 1907.36 nm are 23.53 W and 68.26%, respectively. This study illustrates that fine-tuning the pump wavelength is an effective way to improve the slope efficiency and output power of the Ho:YAG laser at room temperature.

Introduction

A 2.1 μm laser is located in the atmospheric window and widely used in applications such as laser medical1, material processing2, optical communication lidar detection and ranging systems3, and the optical parametric oscillators4,5. At present, the main approach to obtain lasers with wavelengths at 2.1 μm is to pump a Ho-doped crystal with a 1.9 μm laser that coincides with the absorption wavelength peak of Ho-doped crystal. A solid-state laser pumped by a 1.9 µm laser can achieve a 2.1 µm laser with high power, high beam quality, and narrow linewidth at room temperature. Until now, the Tm-doped solid-state and Tm-doped fiber lasers were used as the pump sources in a high power Ho:YAG laser owing to the better beam quality and higher power. Shen et al. reported a Ho:YAG laser pumped with a Tm:YLF laser at 1907.8 nm, and the output power was 103 W with a slope efficiency of 67.8%6. Pumping the Ho:YAG laser with a Tm-doped fiber laser is a more compact approach due to qualities such as simpler thermal management, higher conversion efficiency, and smaller volume. An output power of 36 W for the Ho:YAG laser pumped at 1907 nm by Tm-doped fibre laser has been reported by Antipov et al.7.

Using a narrow linewidth pump source is an effective way to increase the target laser efficiency8,9. The central wavelength and linewidth of a pump laser have a great influence on the Ho:YAG laser due to the narrow absorption wavelength peak of Ho:YAG crystal at 1.9 μm. Therefore, some research on the Ho:YAG laser has concentrated on narrow linewidth pump sources. Currently, lasers using volume Bragg grating (VBG) have the ability to select wavelength and narrow linewidth. Chen et al. reported a Tm:YLF laser with a VBG, and the output power was 15.5 W at 1908.1 nm, corresponding to the linewidth of 0.15 nm10. Wei et al. reported a narrow linewidth Tm:YLF laser with a VBG, and the output power was 202 W at 1908.5 nm, corresponding to the linewidth of 0.57 nm11. At present, there are few reports about tunable Tm:YLF lasers. Sheintop et al. reported a tunable Tm:YLF laser, corresponding to a tunable range of 1926–1961 nm12. Here, the absorption cross-section of the Ho:YAG crystal at 1.91 μm was higher than that at 1.93 μm, which assisted in the absorption of the pump light and achieved higher output power13. Therefore, a Ho:YAG laser pumped by a tunable 1.91 μm laser is an attractive method to obtain higher slope efficiency and output power.

This study proposes a Ho:YAG laser pumped by a narrow linewidth tunable 1.91 μm laser. The pump source was a Tm:YLF laser with a tunable range of 1906.04–1908.83 nm, corresponding to a linewidth of less than 0.41 nm. The beam quality of the Tm:YLF laser remains almost constant over the entire tuning range, which was favorable for pumping the Ho:YAG laser. The output characteristics of the Ho:YAG laser at different pump wavelengths are measured.

Experimental setup

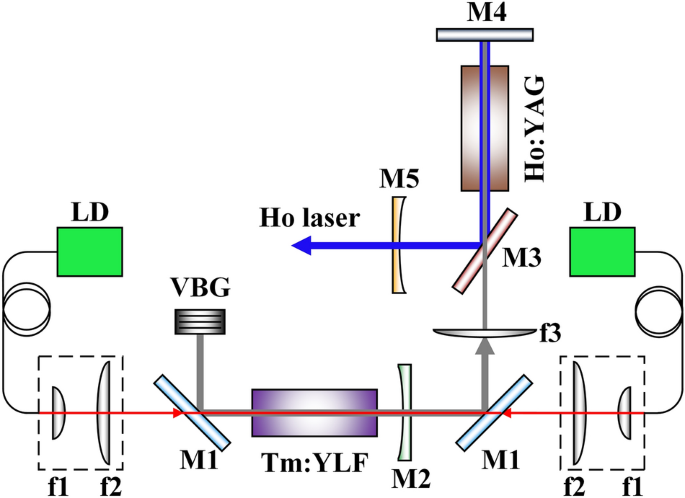

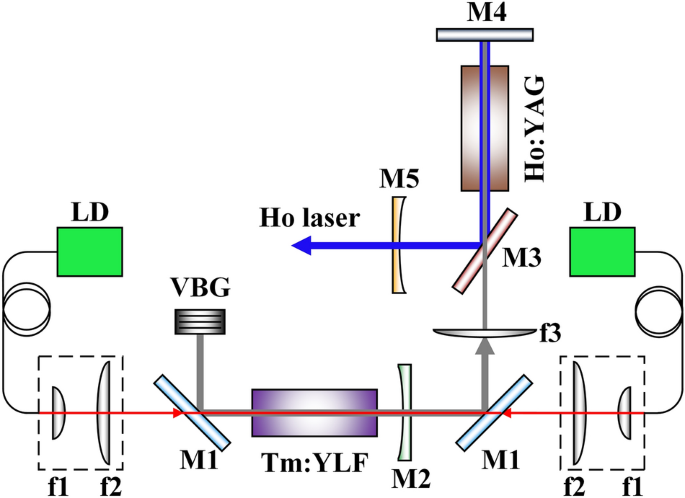

The experimental setup of the Ho:YAG laser pumped by Tm:YLF is shown in Fig. 1.

Experimental setup of the Ho:YAG laser pumped by Tm:YLF laser.

A double-ended pump structure was used for the Tm:YLF laser. The pump sources were two fiber-coupled laser diodes (LDs) with a power of 80 W and central wavelength of 793 nm. The pump beams were focused on the Tm:YLF crystal with a diameter of 0.75 mm using beam shaping devices. The M1s were coated with high transmittivity at 793 nm and high reflection at 1.9 μm. M2 was a plano-concave mirror with a transmittance of 20% at 1.9 μm, and its radius of curvature was 150 mm. The transverse size and thickness of the VBG were 4 × 3 mm2 and 5 mm, respectively. The diffraction efficiency was greater than 99.0% at 1905.5 nm at room temperature. The structure was mounted on a copper heat sink that could be controlled from room temperature to 210 °C. The entire cavity consisted of a plano-concave mirror M2, 45° dichroic mirror M1, and VBG. The cavity length of the Tm:YLF laser was 85 mm in this experiment. The Tm:YLF crystal was a-cut with a size of 1.5 × 4 × 30 mm3 and doping concentration of 2.0 at.%. Both ends of the Tm:YLF crystal were coated with antireflection coatings of 793 nm and 1.9 μm, respectively. Additionally, the crystal was wrapped using an indium foil and fastened into a copper holder, which was water cooled to 20 °C.

A single-end-pump structure was used for Ho:YAG laser. The pump lasers were focused into the Ho:YAG crystal with a beam diameter of approximately 0.95 mm by lens f3. M3 was a 45° dichroic mirror with high transmittivity at 1.9 μm and high reflection at 2.1 μm. M4 was coated with high transmittivity at 1.9 μm and high reflection at 2.1 μm. M5 was a plano-concave mirror with a transmittance of 20% at 2.1 μm, and the radius of curvature was 300 mm. Furthermore, the entire cavity consisted of a plano-concave mirror M5, 45° dichroic mirror M3, and plane mirror M4. The cavity length of the Ho:YAG laser was 115 mm. The Ho:YAG crystal had a diameter of 4 mm, length of 50 mm, and doping concentration of 0.8 at.%. The two end surfaces of the crystal were anti-reflection (R ≤ 0.3%) coated at 1.9 and 2.1 μm. Lastly, the crystal was wrapped in a copper holder filled with flowing water and the temperature was controlled at 20 °C.